Linear and modular programming are both discussed, as well as different types of Siemens PLC engineering software and PLC program memory usage.īasic Ladder Diagram Programming for Siemens PLCs 280 This class discusses the basic concepts of programming Siemens PLCs. This class provides a brief description of the different varieties of SIMATIC PLCs and a more in-depth overview of Modular PLCs in particular. This class provides an overview of the different types of HMI devices and systems used by Siemens PLCs. In addition, the class discusses PLC device addressing and configuration, as well as PLC tag usage. This class covers the variety of PLC input/output modules and devices. This class provides a comprehensive look at the techniques and devices used by Siemens PLCs to communicate with other devices. Binary, octal, decimal, and hexadecimal numbers are covered, as well as different types of integers and scientific notation. This class reviews the basic types of numbers, codes, and data used by Siemens PLCs. Numbers, Codes, and Data Types for Siemens PLCs 220 It also covers the methods of communication between hardware components and discusses basic guidelines for PLC installation. This class describes the basic hardware components of Siemens PLCs. This class introduces the parts and operations of Siemens programmable logic controllers (PLCs) and describes the functions and different programming languages you will find on these PLCs. Students also learn about how Siemens PLCs communicate with other devices, the input/output modules, HMI devices, and modular PLCs, among other more advanced topics. Topics covered include the types of operations common to PLCs, the basic hardware components, installation guidelines, and the data and codes common to Siemens PLCs. These classes address a very powerful family of PLC, Siemens SIMATIC PLCs.

#Curso siemens step 7 full#

The Siemens SIMATIC family of control products includes a variety of PLC models designed to handle the full range of applications. For example, PLCs are used in traffic signals, pharmaceutical manufacturing, theme park attractions, and automotive assembly, just to name a few.

Manufacturers use PLCs when they need flexible yet precise electrical control over any range of processes that coordinate inputs and outputs. The maintenance engineer should also be capable of making an (original) backup of the program and be able to load it into the PLC.The "brains" behind many automated processes, programmable logic controllers (PLCs) are incredibly sophisticated and widely used in industry today.

#Curso siemens step 7 install#

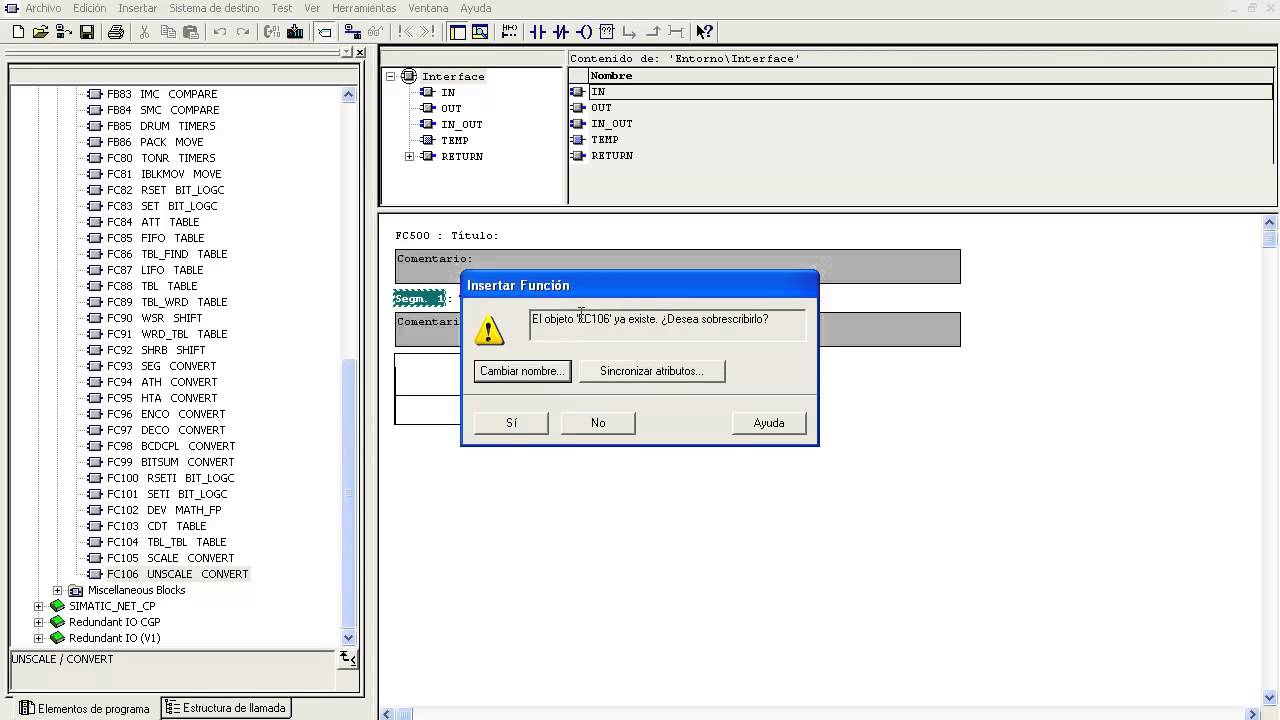

The maintenance engineers should be capable of making small changes to the program. Programming and documenting the program is of less importance. With regard to PLC’s and programming software, the maintenance engineer needs to be able to access specific parts of the program and to examine the I/O status. One needs to have sufficient knowledge of the equipment, coupled with knowledge of the installation to be able to diagnose the problem and then solve the problem. This course recognises that maintenance personnel cannot build up a profound technical knowledge of all the equipment to be maintained. Global Contents Maintenance personnel are often confronted with equipment from several manufacturers.

0 kommentar(er)

0 kommentar(er)